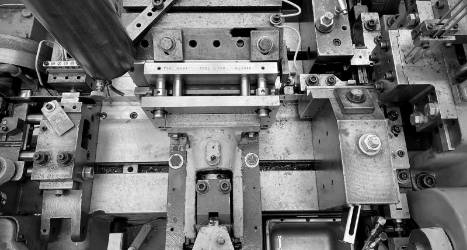

Metal stamping is a fast, cost-effective type of metal forming for creating precise parts from metal materials such as sheets and coils. Keats Manufacturing Co. is a leading provider of comprehensive and accurate metal stamping, finishing, and value-added services. We can guide you through the metal stamping process to help confirm what procedures and finishes are necessary for your product, and we have the expertise to avoid the pitfalls of metal forming by using industry best practices in your product design.

Metal Stamping Design Considerations

Sheet metal and coiled metal wire are the most common materials used in metal stamping processes. To create well-formed, accurate, and virtually identical products, it’s important to consider these elements when creating metal stamping designs:

-

Bend radius

The material must generally bend in a single orientation, and the inside bend radius should equal the sheet thickness at a minimum. -

Grooves, holes, and slots

Keeping the diameter of grooves, holes, and slots equal to or larger than sheet thickness results in better form with fewer burrs and bulges. Keeping the holes apart at a distance of at least twice the thickness of the material can also reduce bulging and deformation. -

Material needs and characteristics

Different metals and alloys have different attributes, including different degrees of resistance to bending, strength, formability, and weight. Some metals will respond better to design specifications than others; conversely, designers will need to take the advantages and limitations of their chosen metal into consideration. -

Tolerances

Determine the acceptable tolerance levels for your project. Achievable tolerances will vary based on the metal type, the design demands, and the machining tools used. -

Wall thickness

Consistent wall thickness throughout a product is typically ideal. If a part has walls with different thicknesses, then it will be subject to different bending effects, resulting in deformation or falling outside of your project’s tolerances.

Possible Defects and How to Avoid Them

Some of the most common defects in metal stamped products are:

-

Bending damage

Parts with dramatic bends are particularly vulnerable to cracks, especially if they’re made from stiff metals with little plasticity. If the bend is parallel to the grain direction of the metal, it could form long cracks along the bend. -

Hole deformation

Three-dimensional metal parts with holes often go through hole punching first and bending into shape second. If the holes are too close to the bent edge, they can stretch or deform. -

Insufficient hole spacing

If a hole isn’t a proper distance from the edge of a piece, which is a minimum of twice the part’s thickness, then the strip of material between the hole and the edge will bulge outward. -

Stamped edge burrs

Cutting and stamping tools can shear metal edges, causing sharp burrs along the bottom of the edge. This can make the piece sharp to the touch, lead to a blemished finish, or even negatively impact the dimensionality of the finished product.

These defects are often the result of poor stamping processes and deviation from best practices.

Choose Precision Metal Stamping Services From Keats Manufacturing

Keats Manufacturing is a custom metal stamping supplier specializing in high-quality metal stamping, wire form, and assembly services. Our engineering and production teams have the experience and skill to tackle your project, no matter how complex, all at an affordable cost.

To learn more about our stamping capabilities for custom parts, low- and high-volume production runs, and more or for pricing details

Contact Us Request a Quote