Keats Manufacturing Company has been in business for over 50 years. During that time, we have developed an outstanding reputation for providing excellent customer service and industry-leading product quality.

Our responsive, highly knowledgeable customer service team is responsible for part of our reputation; and the rest is our exemplary part quality. We work hard at Keats Manufacturing to ensure that our products are always of the best quality available, and we maintain our high-quality by evolving our processes as technologies become more advanced. Our facilities — Wheeling, IL and Keats Southwest in El Paso, TX — each employ the most advanced technology available to ensure that each of your orders are of unsurpassed quality.

CNC Machining Equipment

In computer numerical control (CNC) machining, machine tools are controlled by highly specialized computer programs. A detailed CAD drawing is created for a part, which is uploaded to the CNC machine’s computer. The software determines the ideal machine process, programs it, and controls the machine during production.

In computer numerical control (CNC) machining, machine tools are controlled by highly specialized computer programs. A detailed CAD drawing is created for a part, which is uploaded to the CNC machine’s computer. The software determines the ideal machine process, programs it, and controls the machine during production.

CNC machining is more precise, more repeatable, and faster than manual machining, and can produce shapes that are drastically more complex, including 3D shapes, manual machining cannot produce. At Keats Manufacturing, we use CNC machining for quick, precise tooling development and for repetitive, high volume jobs that require exceptional precision. This equipment allows us to adapt quickly to changes and develop new manufacturing processes to better serve our customers. The addition of our newest CNC machine from Milltronics USA allows us the capability to build replacement production machine parts such as cams, slides, blocks & die components extremely efficiently and quickly.

MRP System

One key to a smooth production process is an effective material requirements planning (MRP) system.

One key to a smooth production process is an effective material requirements planning (MRP) system.

MRP systems — which are used to plan and schedule production, and control inventory of both raw materials and completed parts — ensure required raw materials are available when needed, and required completed parts are available when deliveries are due. A good MRP system will keep material and product levels at roughly the minimum required levels to help control production costs like storage.

Keats Manufacturing uses an automated, fully-integrated software-based MRP system called JobBoss to plan manufacturing processes, purchasing, and delivery schedules, control inventory, and manage bills of materials.

We also integrate our MRP system to work with our customer portals and unique proprietary MRP systems such as Ariba, Covisint, Plex, and SAP. Our team of 10 dedicated sales and customer service professionals are highly trained on unique customer portal integration and customer specific software requirements. Our MRP system professionals can work with your JIT “Just in Time” delivery / Kan-Ban system to custom print shipping labels as well as update stock levels digitally.

Keyence Digital Visual Inspection Equipment

Because part inspection is every bit as important as quality manufacturing in ensuring only perfect products leave our facilities, we are constantly upgrading our visual inspection equipment.

We employ a range of digital visual inspection equipment from KEYENCE, a globally leading sensing technology manufacturer, at every step of the manufacturing process. Dimensions and tolerances are pre-loaded onto our server — the visual inspection equipment, including high speed machine vision systems, pull a part’s specifications and measure all of them virtually instantaneously on as many as 99 parts at once.

The data measured by the machine is then stored digitally on our server which allows us to implement statistical process control or SPC into our manufacturing process seamlessly. This technology also takes the guesswork of the inspection process since the parts are checked the same way each time.

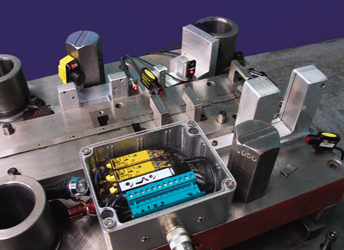

In-Die Camera and Laser Inspection

Another facet of our in-process inspection process is our in-die camera and laser inspection equipment.

This technology yields a number of important benefits. Most notably, it allows us to pinpoint errors before they become problematic, allowing us to reduce scrap, and minimize or eliminate rework time and cost. It is also helpful in eliminating quality control bottlenecks — production no longer needs to be stopped to find and diagnose a problem.

In-Die Sensing Technology

There is no time in your supply chain for unplanned downtime in the manufacturing processes of your parts and components. At Keats Manufacturing, we understand that.

We use in-die sensing technology to achieve precise tool positioning, continuous alignment checks, and emergency press stopping. By using in-die sensing technology, we can drastically reduce damage and unplanned wear to your tools and dies. This allows us to increase not only production, but part quality as well.

We use in-die sensing technology to achieve precise tool positioning, continuous alignment checks, and emergency press stopping. By using in-die sensing technology, we can drastically reduce damage and unplanned wear to your tools and dies. This allows us to increase not only production, but part quality as well.

Work with Keats

These technologies are only a handful of the tools Keats Manufacturing Co. uses to ensure the highest quality parts and assemblies for our customers.

These technologies are only a handful of the tools Keats Manufacturing Co. uses to ensure the highest quality parts and assemblies for our customers.

To learn more about Keats and why we should be part of your supply chain, download our eBook, How to Add Keats to Your Supply Chain, for free today.

Comments are closed