Automotive

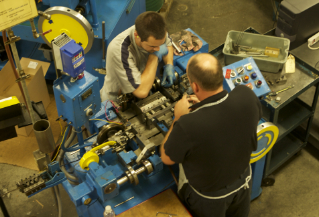

Automotive metal stamping requires extreme precision and attention to detail. With three full-service manufacturing locations, we possess the latest technologies and skills to achieve even the most challenging tolerance windows. Combined, our shops contain over 175 metal-stamping machines. All of our dies are engineered in-house to ensure high-quality cuts.

We first started serving the automotive industry in 1971. Today, nearly every car in North America has at least one Keats part in its assembly.

Keats parts can be found inside the following automotive components and more:

- Seating

- Fuel System

- Front Air Dam Control

- Oil Pump

- Alternator

- Air Filter Housing

- Headlights

- Steering Wheel

- Wheels

Construction

Construction and housing industries rely on components made from metal stamping. This includes every sector of construction: residential, commercial, industrial, research, and government.

In the construction field, long-lasting stamped metal parts are essential to the integrity of the structure. Parts used in construction will endure challenging conditions that can cause rust and corrosion in poorly made parts. At Keats, we understand the importance of durability and longevity, and we have perfected our abilities over the years to allow us to craft dependable metal-stamped parts for construction applications.

Metal stamping is used to create:

- Industrial switches

- Clips

- Power tools

- Hose clamps

- Connectors

- Housings

- Panel fastening systems

- Shields

- Custom assemblies

- Brackets

- Fuse clips

- Fuse boxes

- Heat sinks

- Lighting components

- Shields

- Trusses

Electrical Distribution

In order to reach your home or business, electricity must weave its way through the complex power grid. Effective electrical distribution is required for end users to utilize electrical services reliably.

Keats parts play a critical role in electrical distribution throughout the entire electrical grid. We are capable of manufacturing complex components that are needed throughout the distribution process. We understand that quality is important, and that’s why our tooling comes with a lifetime warranty.

We offer a large variety of parts for circuit breakers, power meters, switches and other electrical distribution products, including:

- Terminals

- Clips

- Brackets

- Contacts

- Ground straps

- Bushings

- Inserts

- Shields

- Springs

- Clamps

- Sleeves

- Covers

- Heat sinks

- Antennas

- Washers

- Cases

- Bus bars

- Fan blades

- Retainers

- Plates

- Socket jaws

Military

Defense and military equipment relies on metal stamped components that are often more complex than other industries. These components also have high standards for quality and reliability. Additionally, military and defense components often come with additional administrative challenges that aren’t found with civilian clients.

Keats Manufacturing is capable of meeting these demands. We have already provided components to military clients and are familiar with the unique regulatory compliance obligations.

We can manufacture:

- Assemblies

- Brackets

- Busbars

- Lead Frames

- Shields

- Terminals

- Wire and Cable Connectors

- And more

General Manufacturing

We understand that some businesses don’t fit into an easily categorized industry. Rest assured, we are capable of manufacturing components with obscure specifications. Our engineering team can take a consultative approach to help design custom components for countless applications. Our sophisticated machinery and knowledgeable employees allow Keats to complete jobs of any size. We can complete just about any custom job related to metal stamping, wire forms, or assemblies.

Work With Keats Manufacturing

Keats Manufacturing is a trusted source for wire forms, small metal stampings, and assemblies. Our shops are equipped with the most sophisticated machining equipment, allowing us to produce high-quality components at competitive prices. We have many custom-made dies that can’t be found from any other manufacturer.

Our engineers and automated systems collect data throughout the manufacturing process allowing us to complete fast and reliable final testing before delivery. Our entire company is designed to meet our primary goal: customer satisfaction.

If you have any questions about our capabilities, feel free to contact us today. Already have a project in mind? You can request a quote anytime.